Merħba fil-websajts tagħna!

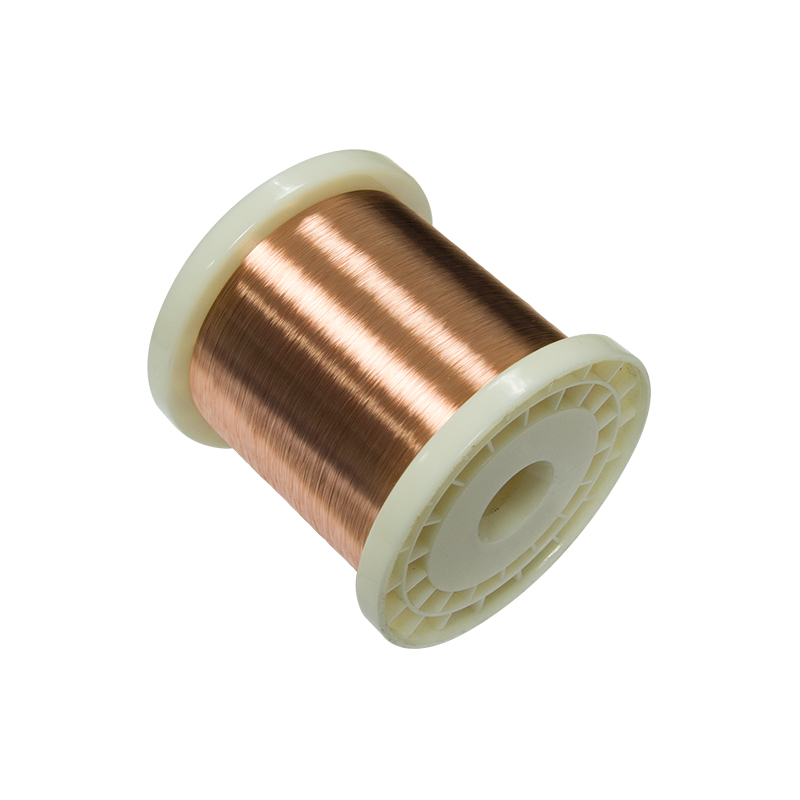

Wajer ta' 1.2mm/1.6mm/2.0mm Tafa 70t Metco Praxair Monel 400 K500 għal Sprej Termali

Monel 400hija liga tan-nikil-ram (madwar 67% Ni – 23% Cu) li hija reżistenti għall-ilma baħar u l-fwar f'temperaturi għoljin kif ukoll għall-melħ u soluzzjonijiet kawstiċi. Alloy 400 hija liga ta' soluzzjoni solida li tista' tiġi mwebbsa biss permezz ta' xogħol fil-kesħa. Din il-liga tan-nikil turi karatteristiċi bħal reżistenza tajba għall-korrużjoni, iwweldjar tajjeb u saħħa għolja. Rata baxxa ta' korrużjoni f'ilma salmastru jew baħar li jiċċirkola malajr flimkien ma' reżistenza eċċellenti għall-qsim mill-istress tal-korrużjoni fil-biċċa l-kbira tal-ilma ħelu, u r-reżistenza tagħha għal varjetà ta' kundizzjonijiet korrużivi wasslu għall-użu wiesa' tagħha f'applikazzjonijiet marittimi u soluzzjonijiet oħra ta' klorur mhux ossidanti.

Applikazzjonijiet:

* Valvijiet, pompi, xaftijiet, fittings, u qfieli

* Skambjaturi tas-sħana industrijali

* Solventi klorinati

* Torrijiet tad-distillazzjoni taż-żejt mhux raffinat

* Skambjaturi tas-sħana industrijali

* Solventi klorinati

* Torrijiet tad-distillazzjoni taż-żejt mhux raffinat

* Inġinerija marittima

* Tagħmir għall-ipproċessar kimiku u tal-idrokarburi

* Tankijiet tal-gażolina u tal-ilma ħelu

* Imlampi tal-petroleum mhux raffinat

* Ħiters li jneħħu l-arja

* Ħiters tal-ilma li jfornu l-bojler u skambjaturi oħra tas-sħana

* Tagħmir għall-ipproċessar kimiku u tal-idrokarburi

* Tankijiet tal-gażolina u tal-ilma ħelu

* Imlampi tal-petroleum mhux raffinat

* Ħiters li jneħħu l-arja

* Ħiters tal-ilma li jfornu l-bojler u skambjaturi oħra tas-sħana

| Kompożizzjoni Kimika | |||||||

| Grad | Ni% | Cu% | Fe% | Mn% | C% | Si% | S% |

| Monel 400 | Min 63 | 28-34 | Massimu 2.5 | Massimu 2.0 | Massimu 0.30 | Massimu 0.50 | Massimu 0.024 |

| Monel 400 Marka Internazzjonali | ||||

| L-Istati Uniti | GE | UK | FR | |

| UNS | ĦJAT VDIUV | BS | AFNOR | |

| Monel 400 | N04400 | W.Nr.2.4360 NiCu30Fe | NA 12 | Numru 30 |

| Proprjetajiet Fiżiċi | ||

| Grad | Densità | Punt tat-Tidwib |

| Monel 400 | 8.83 g/ċm3 | 1300ºC-1390ºC |

| Proprjetajiet Mekkaniċi | ||||

| Liga | Saħħa tat-Tensile (Rm N/mm2) | Saħħa tar-rendiment (RP0.2N/mm2) | Titwil (A5%) | HB |

| Monel 400 | 480 | 170 | 35 | ≥331 |

| Standard tal-Produzzjoni | |||||

| Bar | Forġa | Pajp | Folja/Strixxa | Wajer tal-Iwweldjar | |

| Standard | ASTM B164 | ASTM B564 | ASTM B165 | ASTM B127 | ERNiCu-7 |

Wajer ieħor tal-isprej termali

| Oġġett | Kontenut kimiku | Zn | Cd | Pb | Fe | Cu | Bilanċ Totali |

| żingu pur | Valur nominali | ≥99.995 | ≤0.002 | ≤0.003 | ≤0.002 | ≤0.001 | 0.005 |

| Oġġett | Inkonel 625 | Ni95Al5 | 45CT | Monel 400 | Monel 500 | HC-276 | Cr20Ni80 |

| C | ≤0.05 | ≤0.02 | 0.01-0.1 | ≤0.04 | ≤0.25 | ≤0.02 | ≤0.08 |

| Mn | ≤0.4 | ≤0.2 | ≤0.2 | 2.5-3.5 | ≤1.5 | ≤1.0 | ≤0.06 |

| Fe | ≤1.0 | Mhux Applikabbli | ≤0.5 | ≤1.0 | ≤1.0 | 4.0-7.0 | Mhux Applikabbli |

| P | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.02 |

| S | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 |

| Si | ≤0.15 | ≤0.2 | ≤0.2 | ≤0.15 | ≤0.5 | ≤0.08 | 0.75-1.6 |

| Cu | Mhux Applikabbli | Mhux Applikabbli | Mhux Applikabbli | mistrieħ | 27-33 | Mhux Applikabbli | Mhux Applikabbli |

| Ni | mistrieħ | mistrieħ | mistrieħ | 65-67 | mistrieħ | mistrieħ | mistrieħ |

| Co | Mhux Applikabbli | Mhux Applikabbli | Mhux Applikabbli | Mhux Applikabbli | Mhux Applikabbli | Mhux Applikabbli | Mhux Applikabbli |

| Al | ≤0.4 | 4-5 | Mhux Applikabbli | ≤0.5 | 2.3-3.15 | Mhux Applikabbli | Mhux Applikabbli |

| Ti | ≤0.4 | 0.4-1 | 0.3-1 | 2.0-3 | 0.35-0.85 | Mhux Applikabbli | Mhux Applikabbli |

| Cr | 21.5-23 | ≤0.2 | 42-46 | Mhux Applikabbli | Mhux Applikabbli | 14.5-16 | 20-23 |

| Nb | 3.5-4.15 | Mhux Applikabbli | Mhux Applikabbli | Mhux Applikabbli | Mhux Applikabbli | Mhux Applikabbli | ≤1.0 |

| Mo | 8.5-10 | Mhux Applikabbli | Mhux Applikabbli | Mhux Applikabbli | Mhux Applikabbli | 15-17 | Mhux Applikabbli |

| V | Mhux Applikabbli | Mhux Applikabbli | Mhux Applikabbli | Mhux Applikabbli | Mhux Applikabbli | ≤0.35 | Mhux Applikabbli |

| W | Mhux Applikabbli | Mhux Applikabbli | Mhux Applikabbli | Mhux Applikabbli | Mhux Applikabbli | 3.0-4.5 | Mhux Applikabbli |

| Impuritajiet | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 |

3. Ċ276wajer tal-isprej termali

Ismijiet Komuni: Oxford Alloy® C-276 FM C-276 Techalloy 276

Standard: AWS A5.14, ERNiCrMo-4/ ASME II, SFA-5.14, UNS N10276 Werkstoff Nr. 2.4886 ISO SNi6276 Ewropa NiCrMo16Fe6W4

KOMPOŻIZZJONI KIMIKA (%)

| C | Si | Mn | S | P | Ni | Co |

| ≤0.02 | ≤0.08 | ≤1.0 | ≤0.03 | ≤0.04 | Mistrieħ | ≤2.5 |

| W | V | Fe | Cu | Cr | Mo | oħrajn |

| 3.0-4.5 | ≤0.35 | 4.0-7.0 | ≤0.5 | 14.5-16.5 | 15-17 | <0.5 |

Ikteb il-messaġġ tiegħek hawn u ibgħatu lilna

Kategoriji ta' prodotti

-

Telefon

-

E-mail

-

Whatsapp

-

WeChat

Ġudija

150 0000 2421

-

Fuq