Merħba fil-websajts tagħna!

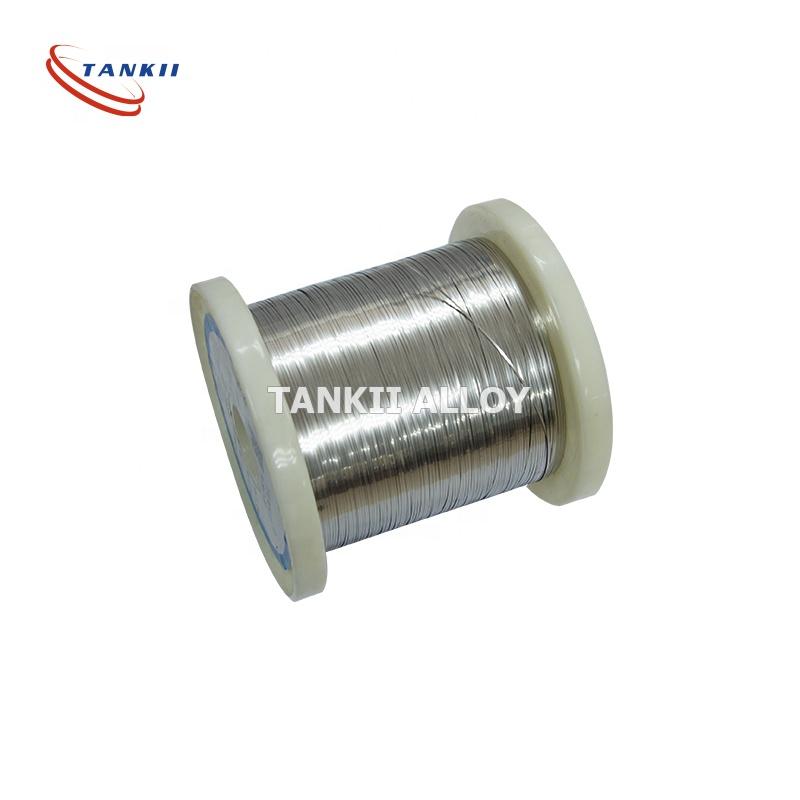

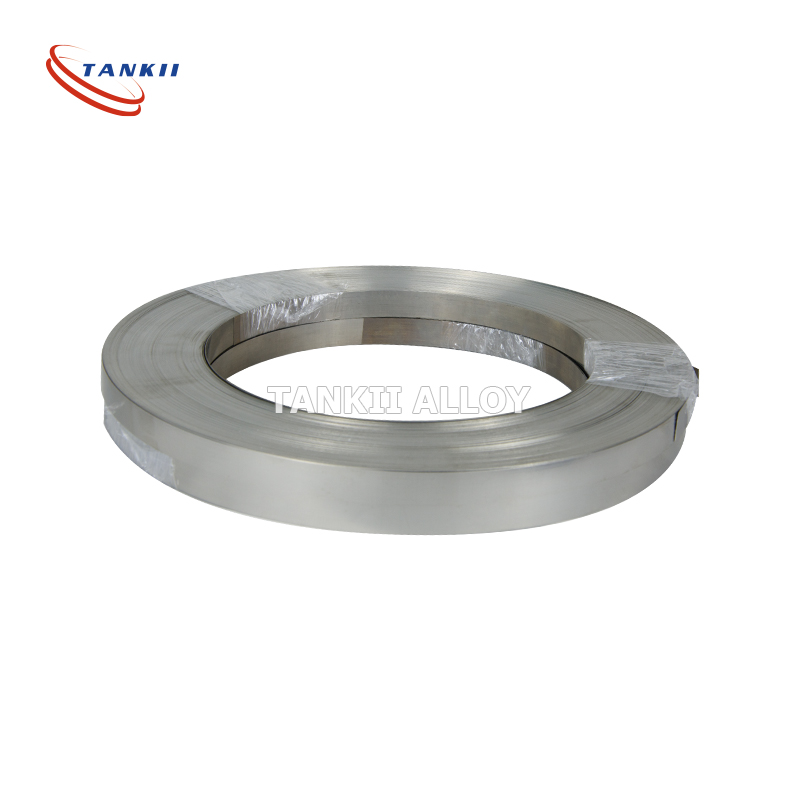

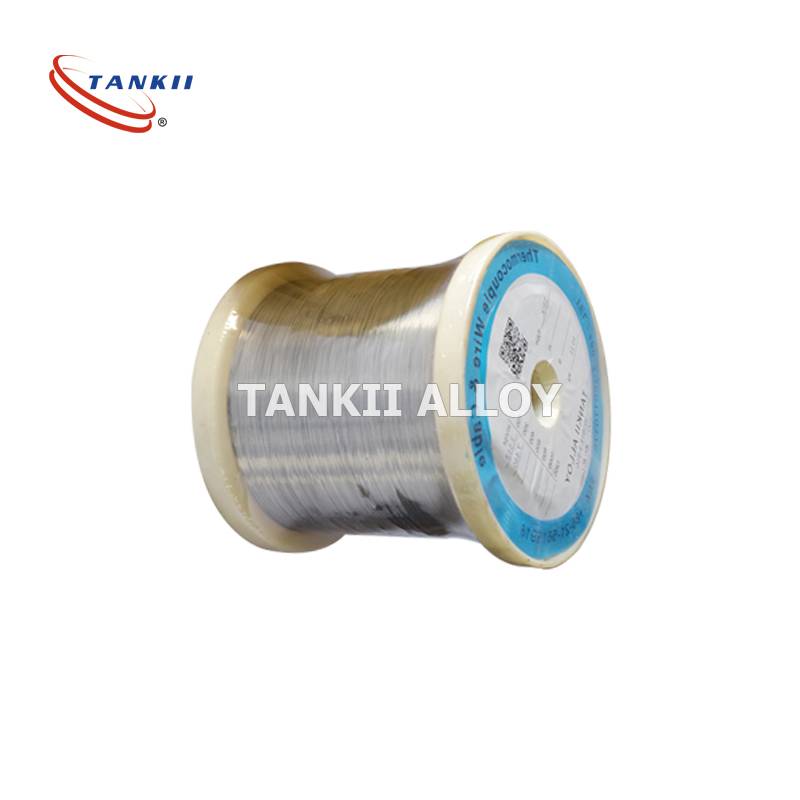

Wajer ċatt u strixxa tal-element tat-tisħin FeCrAl 0cr23al5 mill-fabbrika

Wajer ċatt tal-element tat-tisħin FeCrAl 0cr23al5 &strixxamill-fabbrika

| Grad | 0Cr23Al5 |

| Daqs | ħxuna: 0.05-3mm wisa': 4-250mm |

| Wiċċ | qtugħ qawwi |

| Piż | 1-3kg/roll, skont il-kwantità tal-klijenti |

| Reżistività | 1.3±0.05μΩ.m |

| Ebusija (HV) | 180-210HV |

| Titwil | ≥16% |

| Grad | L-ogħla temperatura | Reżistività | Ebusija | Saħħa tensili | Titwil |

| 0Cr13Al4 | 1050℃ | 1.25±0.05μΩ.m | 180-210HV | ≥550N/mm22 | ≥16 |

| 0Cr15Al5 | 1100℃ | 1.3±0.05μΩ.m | 180-210HV | ≥550N/mm2 | ≥16 |

| 0Cr21Al6Nb | 1300℃ | 1.42±0.05μΩ.m | 200-240HV | 750N/mm2 | ≥12 |

| Cr20Ni80 | 1200℃ | 1.09±0.05μΩ.m | 180-220HV | 750N/mm2 | ≥20 |

| Cr15Ni60 | 1150℃ | 1.12±0.05μΩ.m | 175-210HV | 750N/mm2 | ≥20 |

| Cr20Ni35 | 1100℃ | 1.04±0.05μΩ.m | 180-220HV | 750N/mm2 | ≥20 |

| Cr25Ni20(310S) | 1100℃ | 0.86±0.05μΩ.m | 180-220HV | 750N/mm2 | ≥20 |

| Grad | Kompożizzjoni kimika% | ||||||||

| C | P | S | Mn | Si | Cr | Ni | Al | Fe | |

| ≤ | |||||||||

| 0Cr15Al5 | 0.04 | 0.02 | 0.01 | 0.3 | ≤0.5 | 13-14 | <1 | 4.8-5.0 | bilanċ |

| 0Cr21Al6Nb | 0.05 | 0.025 | 0.02 | 0.5 | ≤0.6 | 21-23 | ≤0.6 | 5-7 | bilanċ |

| 0Cr13Al4 | 0.04 | 0.02 | 0.01 | 0.3 | ≤0.5 | 13-14 | <1 | 4.8-5.0 | bilanċ |

| Cr20Ni80 | 0.08 | 0.02 | 0.015 | 0.6 | 0.75-1.6 | 20-23 | bilanċ | <0.5 | ≤1.0 |

| Cr15Ni60 | 0.08 | 0.02 | 0.015 | 0.6 | 0.75-1.6 | 15-18 | 55-61 | <0.5 | bilanċ |

| Cr20Ni35 | 0.08 | 0.02 | 0.015 | 1.0 | 1-3 | 18-21 | 34-37 | - | bilanċ |

| Cr25Ni20 | 0.08 | 0.045 | 0.03 | 2.0 | 0.4-0.6 | 24-26 | 19-22 | - | bilanċ |

Shanghai Tankii ALloy Material Co., Ltd. tiffoka fuq il-produzzjoni ta' liga tan-nikkromu, wajer tat-termokoppja, liga fekrali, liga ta' preċiżjoni, liga tar-ram u n-nikil, liga tal-isprej termali eċċ. fil-forma ta' wajer, folja, tejp,strixxa, virga u pjanċa.

Diġà għandna ċertifikat tas-sistema ta' kwalità ISO 9001 u approvazzjoni tas-sistema ta' protezzjoni ambjentali ISO 14001. Għandna sett komplut ta' fluss ta' produzzjoni avvanzat ta' raffinar, tnaqqis fil-kesħa, tpinġija u trattament bis-sħana eċċ. Aħna kburin ukoll li għandna kapaċità indipendenti ta' R&D.

Ikteb il-messaġġ tiegħek hawn u ibgħatu lilna

Kategoriji ta' prodotti

-

Telefon

-

E-mail

-

Whatsapp

-

WeChat

Ġudija

150 0000 2421

-

Fuq